The products in BRİMAN OCF group are one component and packaged in 750 ML. Multipurpose pu filling foam, EPS-XPS board adhesive pu foam, pu foam clenaer for cleaning gun and new applied foam.

The products in BRİMAN OCF group are one component and packaged in 750 ML. Multipurpose pu filling foam, EPS-XPS board adhesive pu foam, pu foam clenaer for cleaning gun and new applied foam.

BRIMAN Chemicals produce these materials in 750 ML not only under its label but also under private labels of the customers. Beside the avaliability of providing the OCF materials in IBC tanks, barrels or as bulk according to customer and market necessaries.

BRIMAN OCF has many specifications those make it competitive and preferably such;

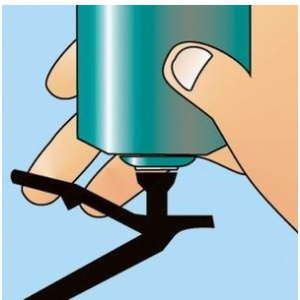

- Multi usage via safety valve system with gun sprayer and straw sytem. Ventile adhesion is prevented due to advanced high techonology.

- Avaliability of usage in four seasons.(-5 °C ile +30 °C)

- It is non flammable of class B2 according to DIN4102.

- Curing between 2-4 hours by moisture.

- One component and ready to use.

- Avaliable for cutting, coationg and painting.

- Durable to water, moisture, steam, corks and molds.

- No volume loss.

- No toxical situation after getting dry.

- Does not contain CFC gas and it is environment and ozone friendly.

- It provides high productivity and ease of operation thanks to the high swelling rate.

- Ideal filling and adhesion to application area.

- Perfect heat and sound insulation.

- Perfect adhesion to all clean application surfaces except Teflone, PE and PP.

UASEG AREAS

- For fixing of doors and windows.

- For holes and cracks filling.

- For insulation of hot and cold water pipelines.

- For fitting of paintings and roof panels.

- For fixing of various material such as; bathtub, showertub etc.

- For all cracks and dilalation fugas.

- For filling, insulation and protecting of all building materials.

In order to get maximum quality the usage instruction of PU foam should be taken into consideration.

For getting an ideal result the products should be kept in room temperature at least 12 hours before usage. Water spraying before and after application will help the curing and sticking to the surface to be faster.

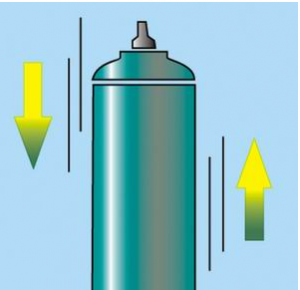

- Preparation of spray: Shake the bottle vigorously for at least 1 minute (30 times).

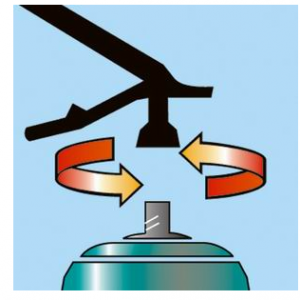

- Wrap the tip of the nozzle. Be careful not to exercise excessive force when tightening.

- Surfaces must be clean and free of dust. Moisten the substrate before applying the foam, moisture will improve extension, adhesion and hardening.

- Apply foam evenly while holding the can upside down. Start at the lowest point. Fill the cavity up to half.

- The temperature of the application area should not be over +30 °C’ and below -5 °C.

- Application in low temperature decrease the quality of the foam and prolong the curing period due to less humidity.

- The foam should not be touched during usage while it is fresh. Unless the cleaning can be done via acetone.

- The foam should be used thrifty due its expanding structure. The output foam can be cut after apprx. 2-4 hours of application.

The PU foam is an aerosol can and its storage conditions and instructions should be taken into considerations.